Development of technology for the manufacturing of foamed polyurethane-rubber composites for the use as damping materials

PUR-GTR

Development of technology for the manufacturing of foamed polyurethane-rubber composites for the use as damping materials

The increase in the number of cars in Poland and other countries causes the introduction of more and more car tires to the market, as well as an increase in the number of tires withdrawn from use. Used tires are burdensome waste, and the issue of their disposal is very important for the natural environment. In Poland, the main method of managing used tires is energy recovery, but it is more effective and more beneficial for the environment than material recycling. Its products are used industrially, but current applications do not guarantee sufficient demand for rubber waste. Using them for the production of polymer-rubber composites seems to be a very promising direction of research. However, in order to use rubber waste as effectively as possible in the production of composites, it is necessary to modify them. As part of the project, a method of modification of continuous rubber dust will be developed using the reactive extrusion process, which will be a very great advantage of the process from an economic and ecological point of view. The modification products will then be used to produce foamed, flexible polyurethane-rubber composites, which will be additionally modified with the use of appropriate flame-retardant and smoke-reducing compounds, which will allow them to meet the increasing fire protection requirements for products used in the construction, automotive and furniture industries.

Members

dr inż. Aleksander Hejna

Principal InvestigatorAleksander Hejna PhD is responsible for directing and supervising the work related to the modification of ground tire rubber and development of flexib...

More...

dr inż. Łukasz Zedler

InvestigatorŁukasz Zedler PhD is responsible for the Stage I of the project - Development of a method for modifying ground tire rubber in a continuous manner. He ...

More...

dr inż. Paulina Kosmela

InvestigatorPaulina Kosmela PhD is responsible for the Stages II and III of the project - Obtaining polyurethane-rubber composites with improved damping propertie...

More...

dr inż. Krzysztof Formela

InvestigatorKrzysztof Formela PhD thanks to his experience and expertise is supporting the Principal Investigator and other team members in all of the project sta...

More...

Mgr inż. Adam Olszewski

PhD studentAdam Olszewski is responsible for the support of Principal Investigator and Investigators in the conducted research works throughout the entire projec...

More...News

Resources

Paulina Kosmela, Kamila Sałasińska, Daria Kowalkowska-Zedler, Mateusz Barczewski, Adam Piasecki, Mohammad Reza Saeb, Aleksander Hejna

Polymers

Fire-Retardant Flexible Foamed Polyurethane (PU)-Based Composites: Armed and Charmed Ground Tire Rubber (GTR) Particles

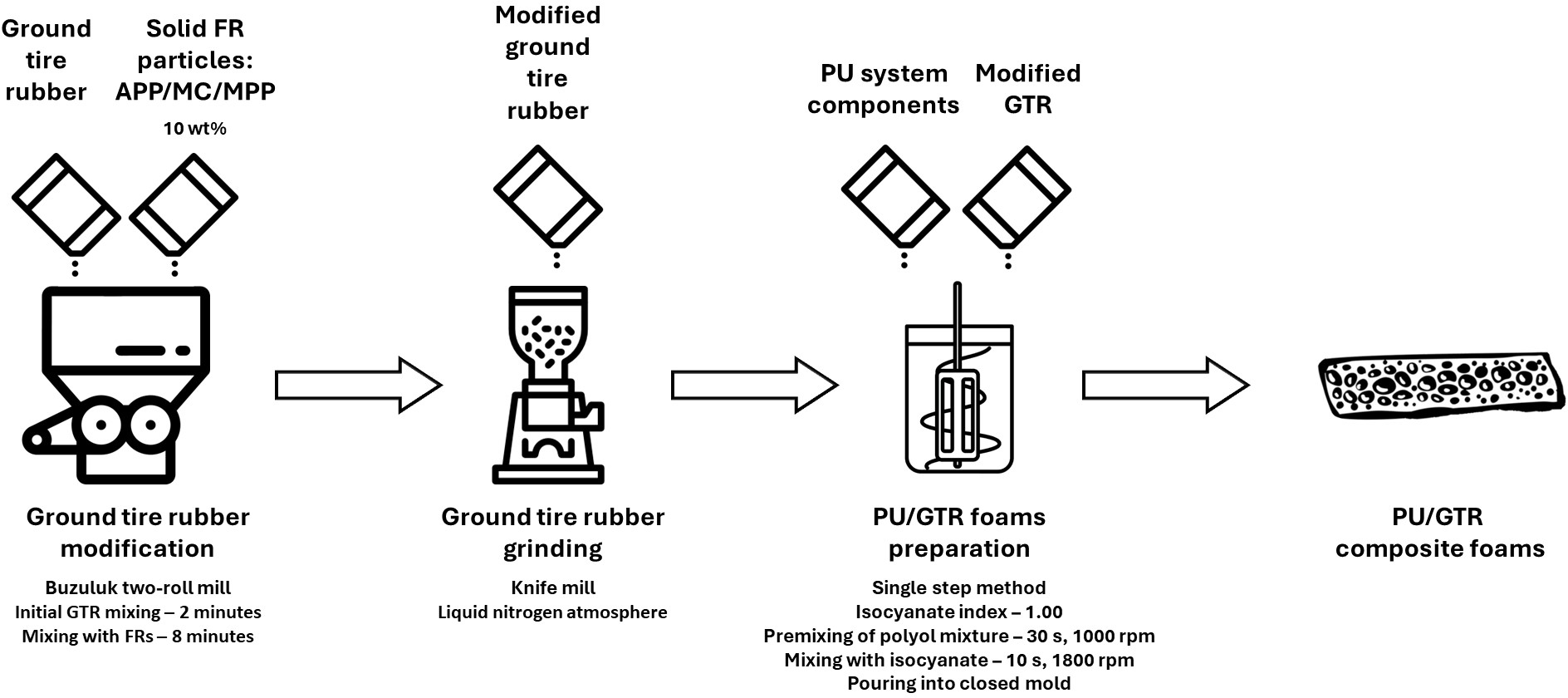

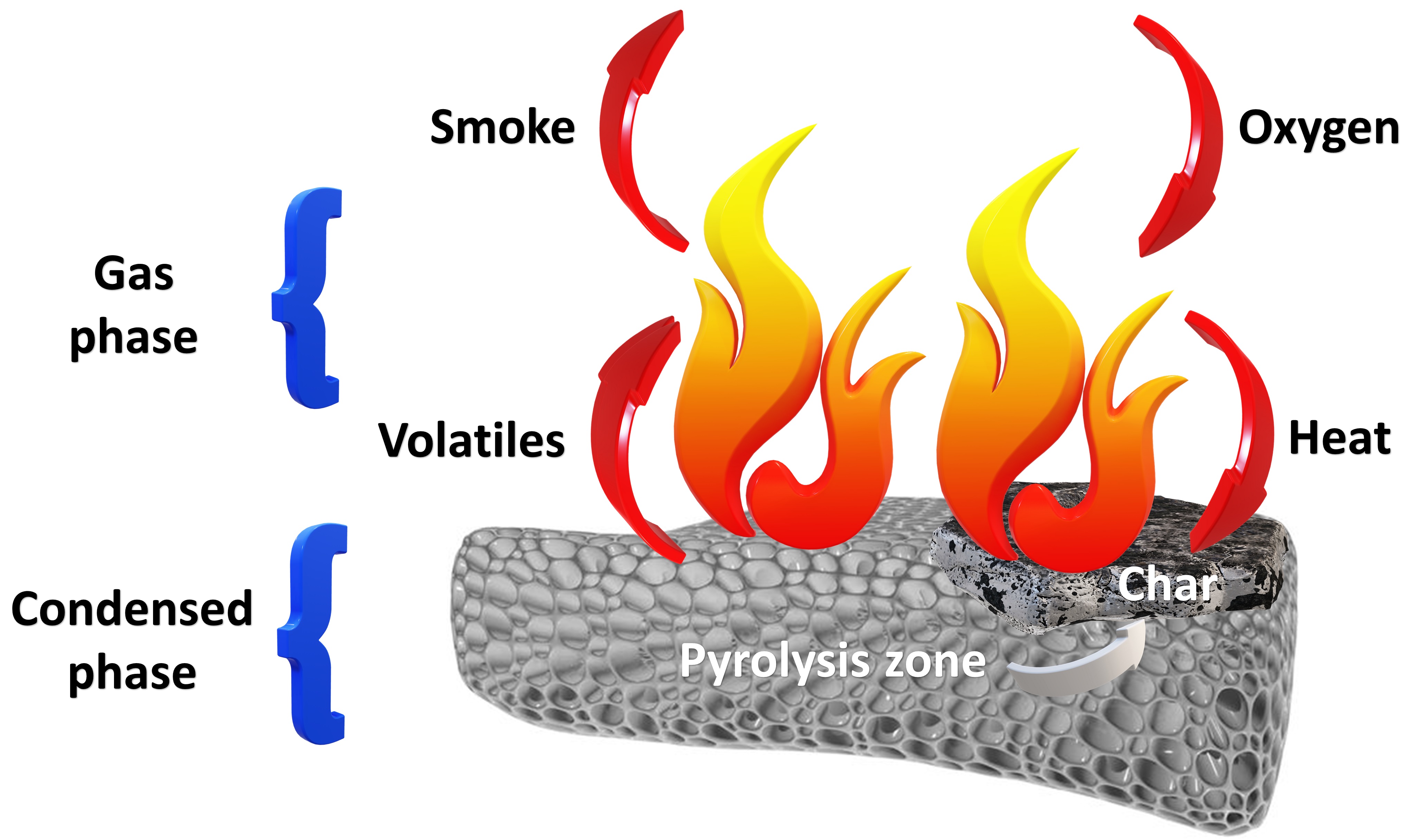

Inadequate fire resistance of polymers raises questions about their advanced applications. Flexible polyurethane (PU) foams have myriad applications but inherently suffer from very high flammability. Because of the dependency of the ultimate properties (mechanical and damping performance) of PU foams on their cellular structure, reinforcement of PU with additives brings about further concerns. Though they are highly flammable and known for their environmental consequences, rubber wastes are desired from a circularity standpoint, which can also improve the mechanical properties of PU foams. In this work, melamine cyanurate (MC), melamine polyphosphate (MPP), and ammonium polyphosphate (APP) are used as well-known flame retardants (FRs) to develop highly fire-retardant ground tire rubber (GTR) particles for flexible PU foams. Analysis of the burning behavior of the resulting PU/GTR composites revealed that the armed GTR particles endowed PU with reduced flammability expressed by over 30% increase in limiting oxygen index, 50% drop in peak heat release rate, as well as reduced smoke generation. The Flame Retardancy Index (FRI) was used to classify and label PU/GTR composites such that the amount of GTR was found to be more important than that of FR type. The wide range of FRI (0.94–7.56), taking Poor to Good performance labels, was indicative of the sensitivity of flame retardancy to the hybridization of FR with GTR components, a feature of practicality. The results are promising for fire protection requirements in buildings; however, the flammability reduction was achieved at the expense of mechanical and thermal insulation performance.

Aleksander Hejna, Paulina Kosmela, Adam Olszewski, Krzysztof Formela, Łukasz Zedler, Adam Piasecki, Katarzyna Skórczewska

Composites Theory and Practice - Preprints

The impact of filler thermomechanical modifications on static and dynamic mechanical performance of flexible foamed polyurethane/ground tire rubber/zinc borate composites

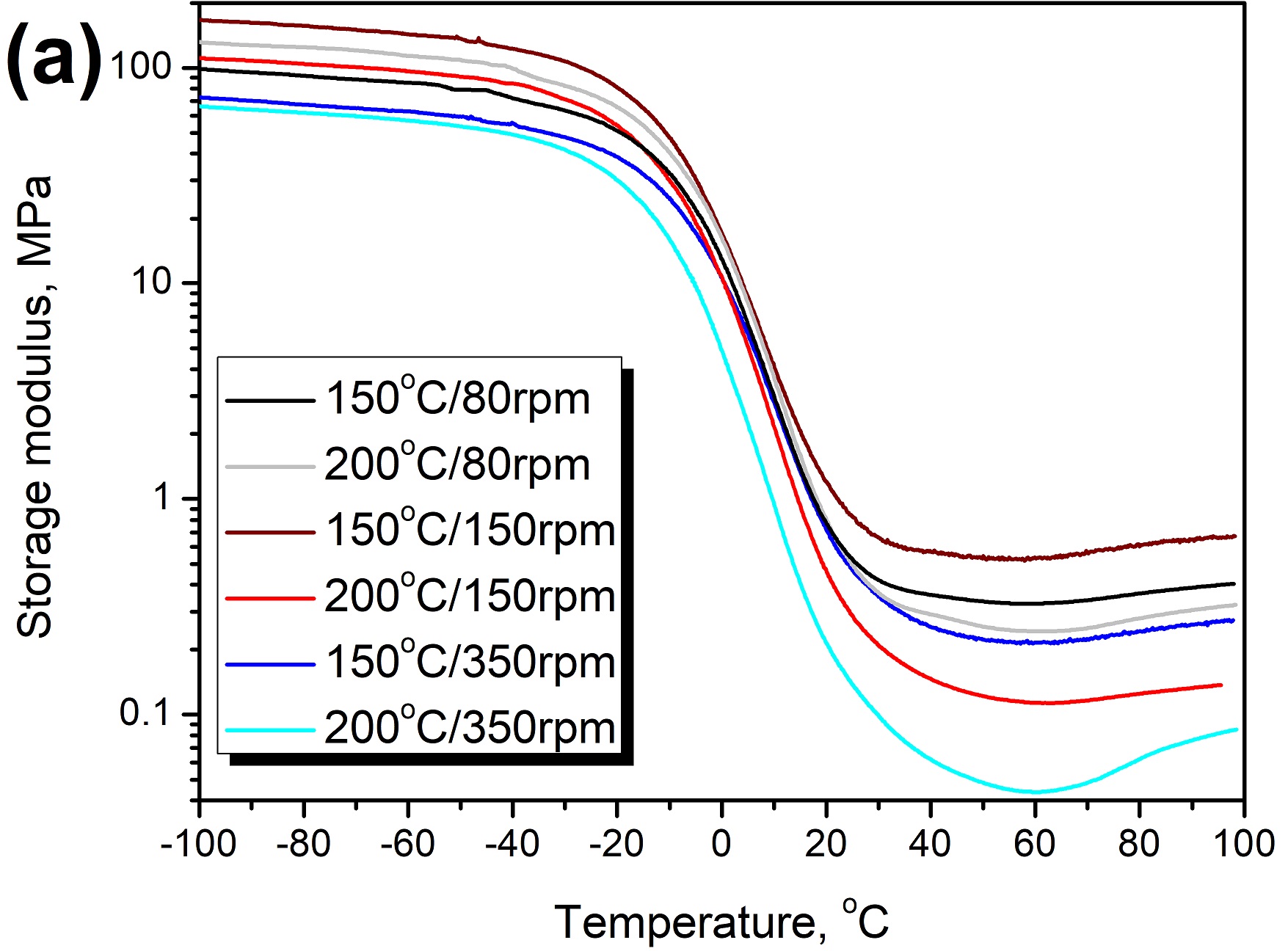

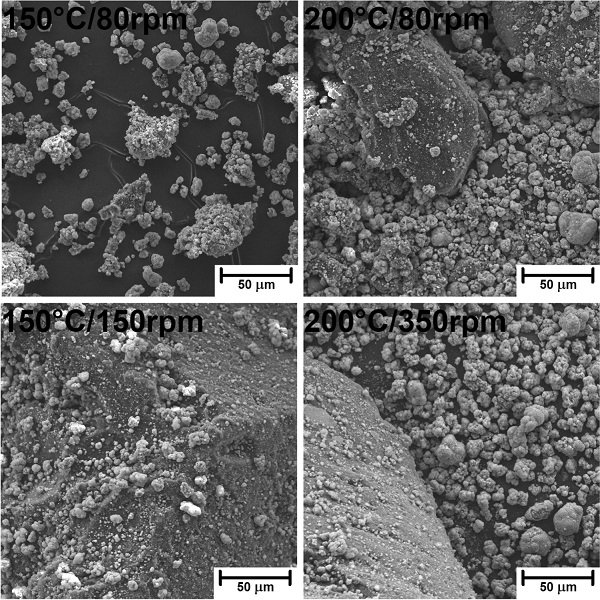

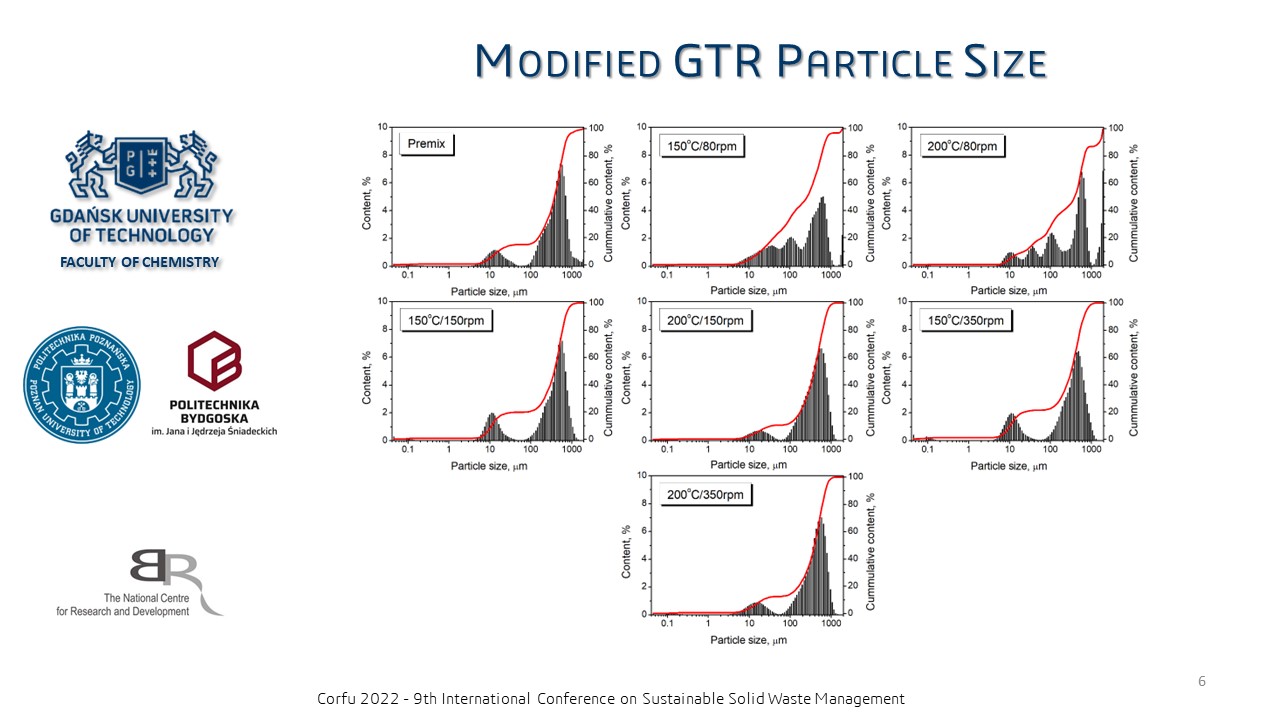

The rapid development of the automotive industry is very beneficial to many aspects of human life, but it is also a very significant environmental burden. The most straightforward impact is related to the generation of exhaust, but the management of post-consumer car parts is also a major challenge. Among them, waste tires are very burdensome due to their enormous numbers. Therefore, it is essential to develop novel, environmentally friendly methods for their disposal, which would reduce their environmental impacts. One of the most promising approaches is shredding, resulting in the generation of ground tire rubber (GTR), which can be introduced into polymeric materials as a filler. The presented work is related to the thermomechanical treatment of GTR in a twin-screw extruder assisted by zinc borate (ZB), whose incorporation is aimed to increase interparticle friction within the extruder barrel. The impact of the treatment conditions on the particle size and surface development of the GTR/ZB compositions was evaluated. Modified GTR was introduced into flexible polyurethane (PU) foams, and the impact on the static and dynamic mechanical performance of the resulting composites was investigated. Increasing the treatment temperature occurred to have an adverse effect on the tensile performance of the composites due to the agglomeration of GTR particles limiting the efficiency of stress transfer, which was also confirmed by dynamic mechanical analysis. On the other hand, increasing the ZB share in the GTR/ZB compositions limited PU disruptions related to the reactivity of the GTR functional groups with isocyanates, which enhanced the mechanical performance of the composites. It was proven that the proposed method of GTR thermomechanical treatment assisted by ZB might benefit the performance of flexible PU foamed composites, which could broaden the application range of GTR and provide novel ways for its efficient utilization.

Aleksander Hejna, Paulina Kosmela, Adam Olszewski, Łukasz Zedler, Krzysztof Formela, Katarzyna Skórczewska, Adam Piasecki, Mariusz Marć, Roman Barczewski, Mateusz Barczewski

Environmental Science and Pollution Research

Management of ground tire rubber waste by incorporation into polyurethane-based composite foams

Rapid economic growth implicated the developing multiple industry sectors, including the automotive branch, increasing waste generation since recycling and utilization methods have not been established simultaneously. A very severe threat is the generation of enormous amounts of post-consumer tires considered burdensome waste, e.g., due to the substantial emissions of volatile organic compounds (VOCs). Therefore, it is essential to develop novel, environmentally friendly methods for their utilization, which would hinder their environmental impacts. One of the most promising approaches is shredding, resulting in the generation of ground tire rubber (GTR), which can be introduced into polymeric materials as filler. The presented work is related to the thermomechanical treatment of GTR in a twin-screw extruder with zinc borate, whose incorporation is aimed to enhance shear forces within the extruder barrel. Modified GTR was introduced into flexible polyurethane (PU) foams, and the impact of modification parameters on the cellular structure, static and dynamic mechanical performance, thermal stability, as well as thermal insulation, and acoustic properties was investigated. Emissions of VOCs from applied fillers and prepared composites were monitored and evaluated. Depending on the treatment parameters, beneficial changes in foams’ cellular structure were noted, which enhanced their thermal insulation performance, mechanical strength, and thermal stability. It was proven that the proposed method of GTR thermomechanical treatment assisted by zinc borate particles might benefit the performance of flexible PU foamed composites and hinder VOC emissions, which could broaden the application range of GTR and provide novel ways for its efficient utilization.

Adam Olszewski, Paulina Kosmela, Adam Piasecki, Mateusz Barczewski, Aleksander Hejna

Polymers

The Impact of Isocyanate Index and Filler Functionalities on the Performance of Flexible Foamed Polyurethane/Ground Tire Rubber Composites

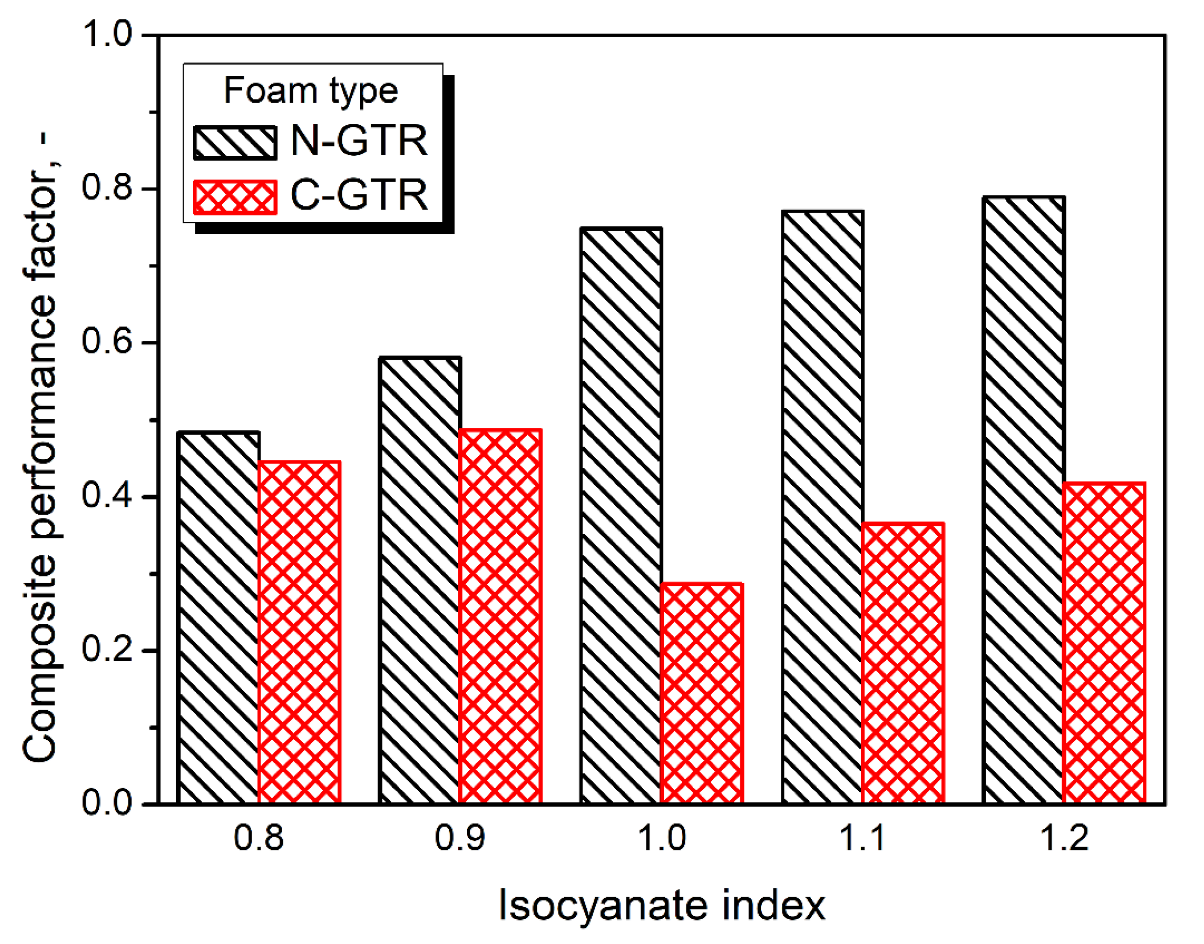

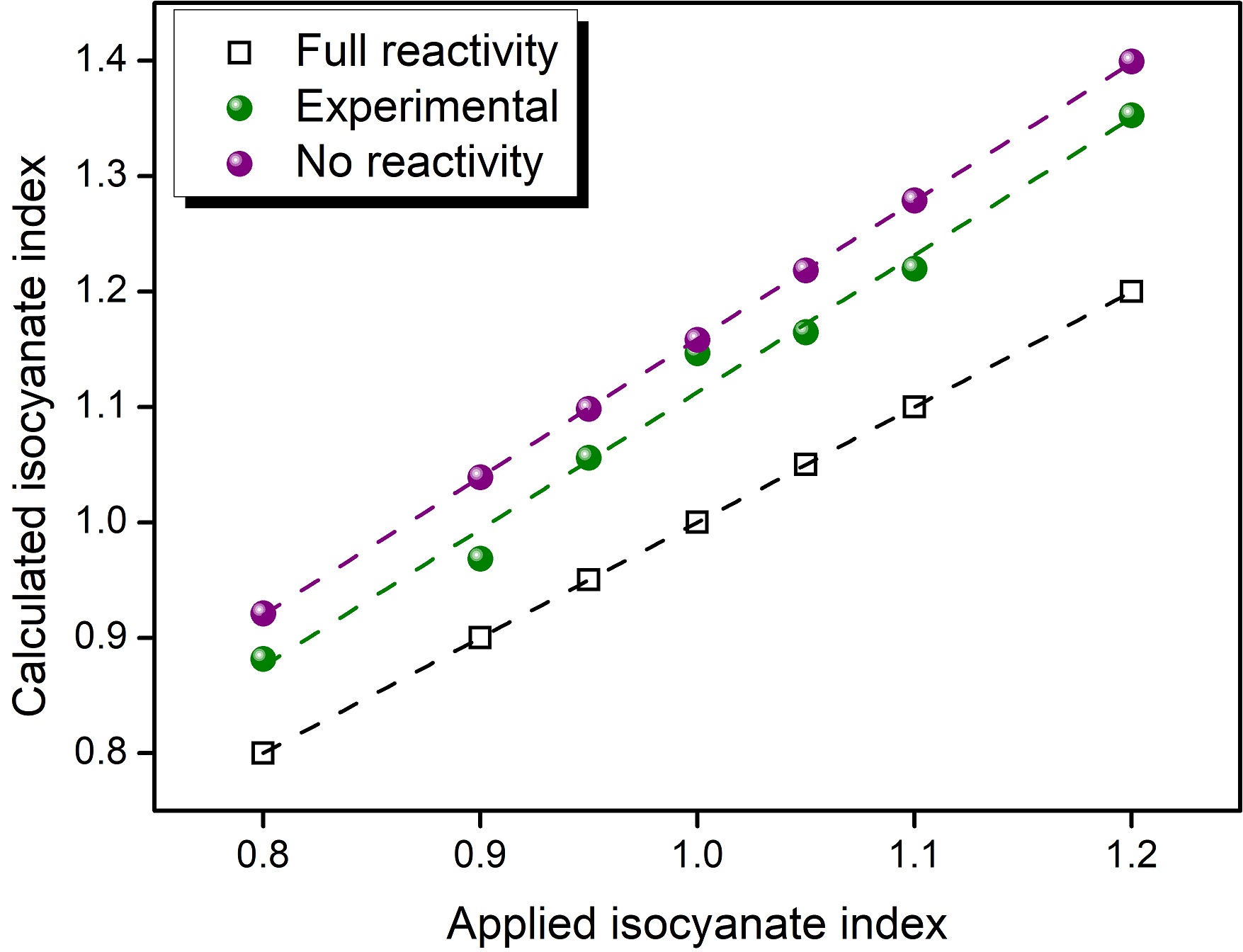

The structure and performance of polyurethane (PU) foams are strongly driven by the stoichiometry of the polyaddition reaction, quantitatively described by the isocyanate index. It determines the balance between isocyanate and hydroxyl groups in the reacting system and is affected by the introduction of additional functionalities originated, e.g., from applied fillers. Nevertheless, this issue is hardly taken into account in research works. Herein, the structure and performance of PU/ground tire rubber (GTR) composites differing in their isocyanate index (from 0.8 to 1.2) and prepared with and without considering the GTR functionalities in formulation development were investigated. Incorporating GTR into the PU matrix led to a reduction in average cell diameter (from 2 to 30% depending on the isocyanate index) compared to unfilled foams. However, formulation adjustments did not show a significant impact on cellular structure. The only decrease in open cell content was noted, from 10% for the 0.9 index to 40% for 1.2. Such changes were related to the increasing strength of the PU cellular structure able to maintain inside the increasing amount of carbon dioxide. On the other hand, considering hydroxyl values of GTR noticeably affected the thermomechanical performance of composites. The shift of glass transition temperature (Tg), even by 10 °C for 1.2 isocyanate index, enhanced the performance of materials, which was expressed in an 8–62% drop in the composite performance factor, pointing to the enhanced reinforcing effect resulting from filler incorporation. The stiffening of foams, related to the variations in PU segmental structure, also caused minor changes in the course of thermal degradation of PU/GTR composites due to the inferior thermal stability of hard segments. The obtained results provide important insights into the development of formulations of PU composites filled with materials containing reactive functional groups able to disrupt the (...)

Adam Olszewski, Paulina Kosmela, Wiktoria Żukowska, Paweł Wojtasz, Mariusz Szczepański, Mateusz Barczewski, Łukasz Zedler, Krzysztof Formela, Aleksander Hejna

Polymers

Insights into Stoichiometry Adjustments Governing the Performance of Flexible Foamed Polyurethane/Ground Tire Rubber Composites

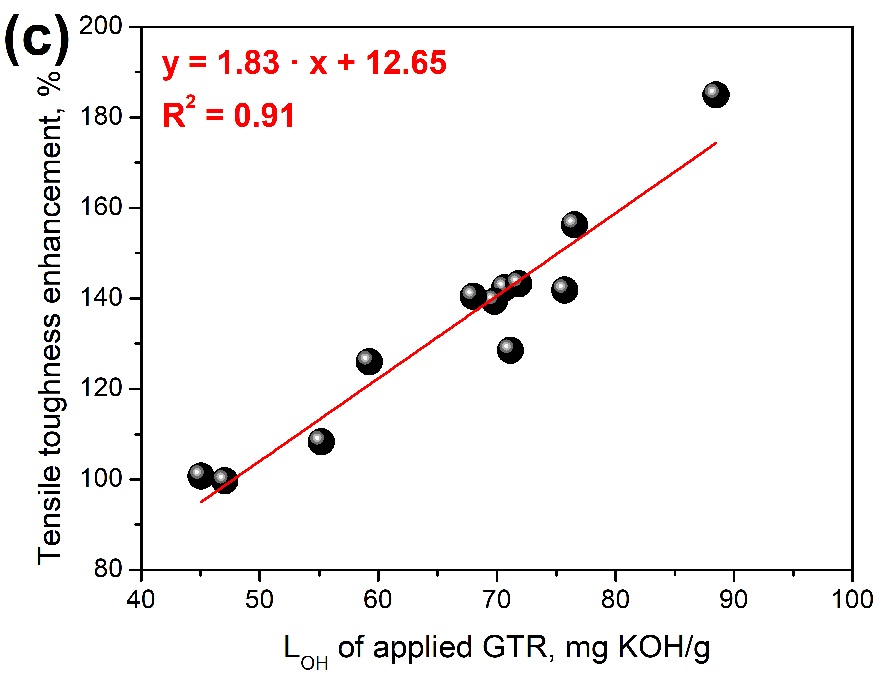

Polyurethanes (PU) are widely applied in the industry due to their tunable performance adjusted by changes in the isocyanate index—stoichiometric balance between isocyanate and hydroxyl groups. This balance is affected by the incorporation of modifiers of fillers into the PU matrix and is especially crucial for PU foams due to the additional role of isocyanates—foaming of the material. Despite the awareness of the issue underlined in research works, the contribution of additives into formulations is often omitted, adversely impacting foams’ performance. Herein, flexible foamed PU/ground tire rubber (GTR) composites containing 12 different types of modified GTR particles differing by hydroxyl value (LOH) (from 45.05 to 88.49 mg KOH/g) were prepared. The impact of GTR functionalities on the mechanical, thermomechanical, and thermal performance of composites prepared with and without considering the LOH of fillers was assessed. Formulation adjustments induced changes in tensile strength (92–218% of the initial value), elongation at break (78–100%), tensile toughness (100–185%), compressive strength (156–343%), and compressive toughness (166–310%) proportional to the shift of glass transition temperatures (3.4–12.3 °C) caused by the additional isocyanates’ reactions yielding structure stiffening. On the other hand, formulation adjustments reduced composites’ thermal degradation onset due to the inferior thermal stability of hard segments compared to soft segments. Generally, changes in the composites’ performance resulting from formulation adjustments were proportional to the hydroxyl values of GTR, justifying the applied approach.

Adam Olszewski, Paulina Kosmela, Adam Piasecki, Wiktoria Żukowska, Mariusz Szczepański, Paweł Wojtasz, Mateusz Barczewski, Roman Barczewski, Aleksander Hejna

Polymers

Comprehensive Investigation of Stoichiometry–Structure–Performance Relationships in Flexible Polyurethane Foams

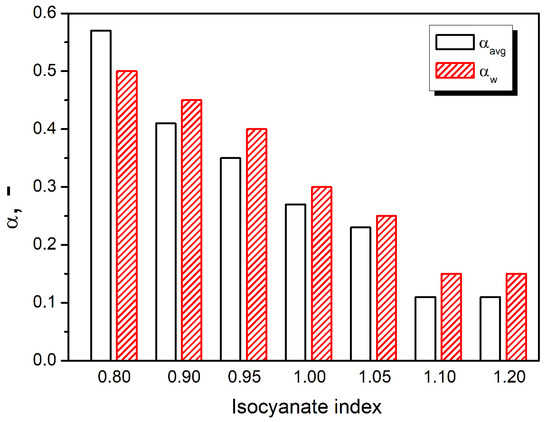

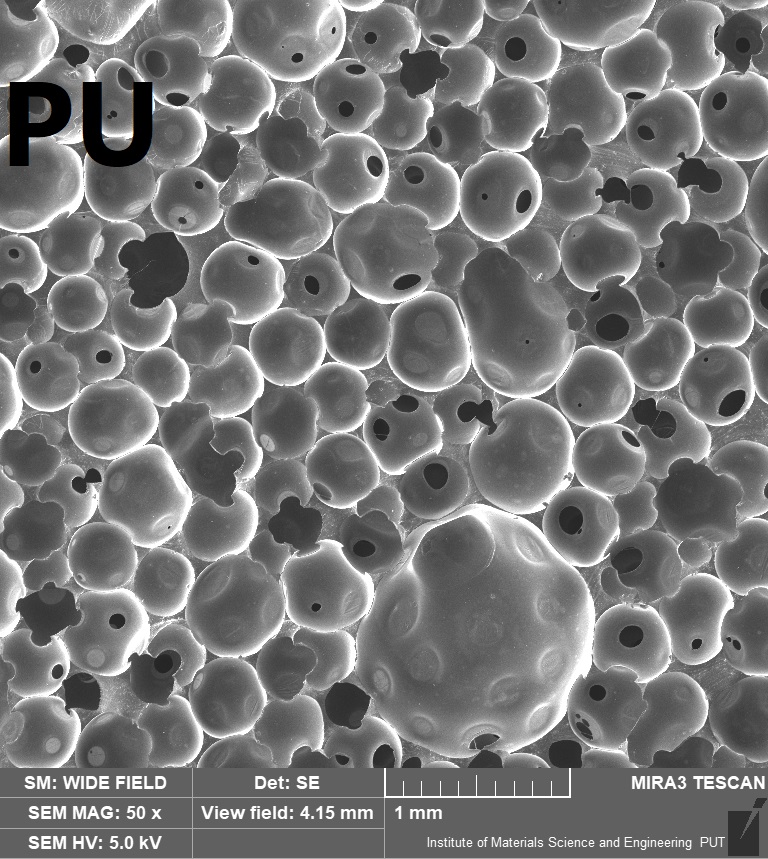

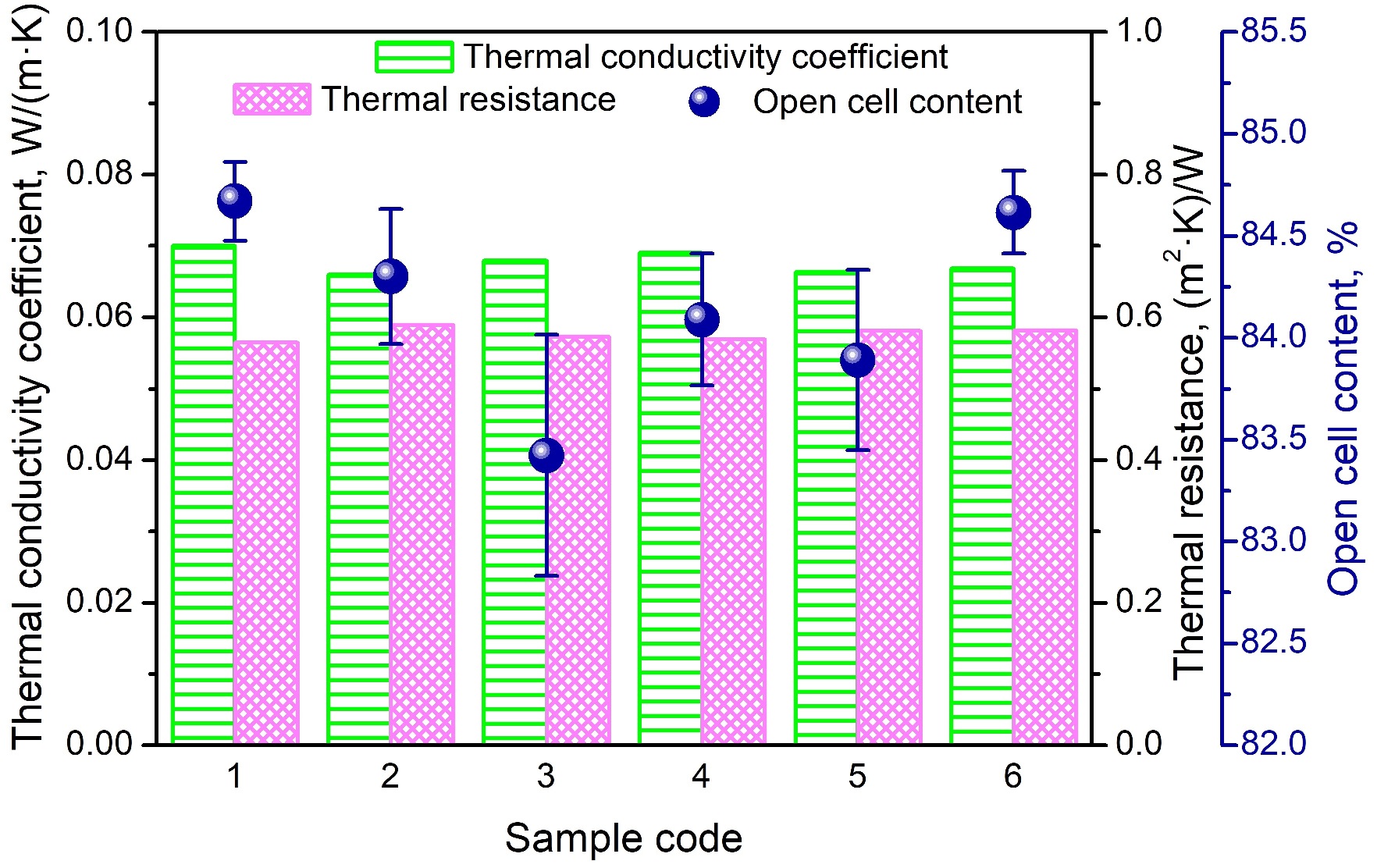

olyurethane (PU) foams are versatile materials with a broad application range. Their performance is driven by the stoichiometry of polymerization reaction, which has been investigated in several works. However, the analysis was often limited only to selected properties and compared samples differing in apparent density, significantly influencing their performance. In the bigger picture, there is still a lack of comprehensive studies dealing with the stoichiometry impact on PU foams’ performance. Herein, flexible PU foams with a similar apparent density but differing in the isocyanate index (IIso) (from 0.80 to 1.20) were prepared. The stoichiometry–structure–performance relationships were investigated considering cellular and chemical structure, as well as the static and dynamic mechanical properties, thermal stability, thermal insulation, and acoustic performance. For IIso of 1.00, the biggest cell diameters of 274 µm were noted, which was 21–25% higher compared to 0.80 and 1.20 values. Increasing IIso reduced open cell content from 83.1 to 22.4%, which, combined with stiffening of structure (rise of modulus from 63 to 2787 kPa) resulting from crosslinking, limited the sound suppression ability around five times. On the other hand, it significantly strengthened the material, increasing tensile and compressive strength 4 and 13 times, respectively. Changes in the foams’ performance were also induced by the glass transition temperature shift from 6.1 to 31.7 °C, resulting from a greater extent of urethane groups’ generation and additional isocyanate reactions. Generally, the presented work provides important insights into preparing flexible PU foams and could be very useful for the future development of these materials.

Wiktoria Żukowska, Paulina Kosmela, Paweł Wojtasz, Mariusz Szczepański, Adam Piasecki, Roman Barczewski, Mateusz Barczewski, Aleksander Hejna

Materials

Comprehensive Enhancement of Prepolymer-Based Flexible Polyurethane Foams’ Performance by Introduction of Cost-Effective Waste-Based Ground Tire Rubber Particles

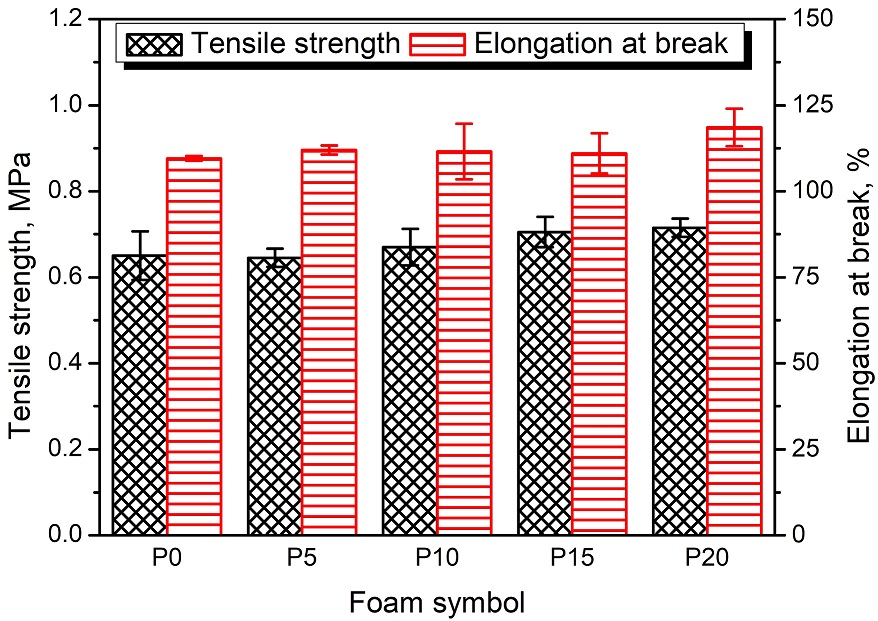

Material innovations in polyurethane (PU) foams should ideally combine performance enhancement, environmental impact limitation, and cost reduction. These goals can be achieved by applying recycled or waste-based materials without broader industrial applications, implicating their low price. Herein, from 5 to 20 parts by weight of ground tire rubber (GTR) particles originated from the recycling of postconsumer car tires were incorporated into a flexible foamed PU matrix as a cost-effective waste-based filler. A two-step prepolymer method of foams manufacturing was applied to maximize the potential of applied formulation changes. The impact of the GTR content on the foams' processing, chemical, and cellular structure, as well as static and dynamic mechanical properties, thermal stability, sound suppression ability, and thermal insulation performance, was investigated. The introduction of GTR caused a beneficial reduction in the average cell diameter, from 263.1 μm to 144.8-188.5 μm, implicating a 1.0-4.3% decrease in the thermal conductivity coefficient. Moreover, due to the excellent mechanical performance of the car tires-the primary application of GTR-the tensile performance of the foams was enhanced despite the disruption of the cellular structure resulting from the competitiveness between the hydroxyl groups of the applied polyols and on the surface of the GTR particles. The tensile strength and elongation at break were increased by 10 and 8% for 20 parts by weight GTR addition. Generally, the presented work indicates that GTR can be efficiently applied as a filler for flexible PU foams, which could simultaneously enhance their performance, reduce costs, and limit environmental impacts due to the application of waste-based material.

Aleksander Hejna, Paulina Kosmela, Wiktoria Żukowska, Adam Olszewski, Łukasz Zedler, Krzysztof Formela, Katarzyna Skórczewska, Adam Piasecki, Roman Barczewski, Mateusz Barczewski

9th International Conference on Sustainable Solid Waste Management Corfu, Greece, 15 - 18 JUNE 2022

Thermomechanically modified ground tire rubber/zinc borate compositions as fillers for flexible polyurethane foams

Rapid economic growth implicated the development of multiple industry sectors, including the automotive branch, which resulted in the generation of multiple wastes since recycling and utilization methods have not been established simultaneously. One of the most severe threats is the generation of enormous amounts of waste tires. Therefore, it is essential to develop novel, environmentally friendly methods for their utilization. One of the most promising approaches is their shredding, resulting in the generation of ground tire rubber (GTR), which can be introduced into multiple polymeric materials as filler. The presented work is related to the thermomechanical treatment of GTR in a twin-screw extruder with zinc borate, whose incorporation is aimed to enhance shear forces within the extruder barrel. Modified GTR was introduced into flexible polyurethane (PU) foams, and the impact of modification parameters on the cellular structure, static and dynamic mechanical performance, thermal stability, as well as thermal insulation, and acoustic properties were investigated. Depending on the treatment parameters, beneficial changes in foams’ cellular structure were noted, which enhanced their thermal insulation performance, mechanical strength, and thermal stability. Generally, it was proven that the proposed method of GTR thermomechanical treatment assisted by zinc borate particles might benefit the performance of flexible PU foamed composites, which could broaden the application range of GTR and provide novel ways for its efficient utilization.

Adam Olszewski, Paulina Kosmela, Łukasz Zedler, Krzysztof Formela, Aleksander Hejna

Materials Proceedings

Optimization of Foamed Polyurethane/Ground Tire Rubber Composites Manufacturing

The development of the automotive sector and the increasing number of vehicles all over the world poses multiple threats to the environment. One of them, probably not so emphasized as others, is the enormous amount of post-consumer car tires. Due to the potential fire threat, waste tires are considered as dangerous waste, which should not be landfilled, so it is essential to develop efficient methods of their utilization. One of the possibilities is their shredding and application of resulting ground tire rubber (GTR) as filler for polymer composites, which could take advantage of the excellent mechanical performance of car tires. Nevertheless, due to the poor compatibility with majority of polymer matrices, prior to the application, surface of GTR particles should be modified and activated. In the presented work, the introduction of thermo-mechanically modified GTR into flexible foamed polyurethane matrix was analyzed. Isocyanates can be found among the compounds applied during manufacturing of polyurethane foams, which are able to react and generate covalent bonds with the functional groups present on the surface of modified GTR. Such an effect can noticeably enhance the interfacial interactions and boost up the mechanical performance. Nevertheless, it requires the adjustment of formulations used during manufacturing of foams. Therefore, for better understanding of the process foams with varying isocyanate index (from 0.8 to 1.2) were prepared with and without taking into account the possible interactions with functional groups of GTR. For comparison, an unfilled matrix and composite containing deactivated GTR were also prepared.

Aleksander Hejna

Materials

Clays as Inhibitors of Polyurethane Foams' Flammability

Polyurethanes are a very important group of polymers with an extensive range of applications in different branches of industry. In the form of foams, they are mainly used in bedding, furniture, building, construction, and automotive sectors. Due to human safety reasons, these applications require an appropriate level of flame retardance, often required by various law regulations. Nevertheless, without the proper modifications, polyurethane foams are easily ignitable, highly flammable, and generate an enormous amount of smoke during combustion. Therefore, proper modifications or additives should be introduced to reduce their flammability. Except for the most popular phosphorus-, halogen-, or nitrogen-containing flame retardants, promising results were noted for the application of clays. Due to their small particle size and flake-like shape, they induce a "labyrinth effect" inside the foam, resulting in the delay of decomposition onset, reduction of smoke generation, and inhibition of heat, gas, and mass transfer. Moreover, clays can be easily modified with different organic compounds or used along with conventional flame retardants. Such an approach may often result in the synergy effect, which provides the exceptional reduction of foams' flammability. This paper summarizes the literature reports related to the applications of clays in the reduction of polyurethane foams' flammability, either by their incorporation as a nano-filler or by preparation of coatings.

Paulina Kosmela, Adam Olszewski, Łukasz Zedler, Paulina Burger, Adam Piasecki, Krzysztof Formela, Aleksander Hejna

Materials

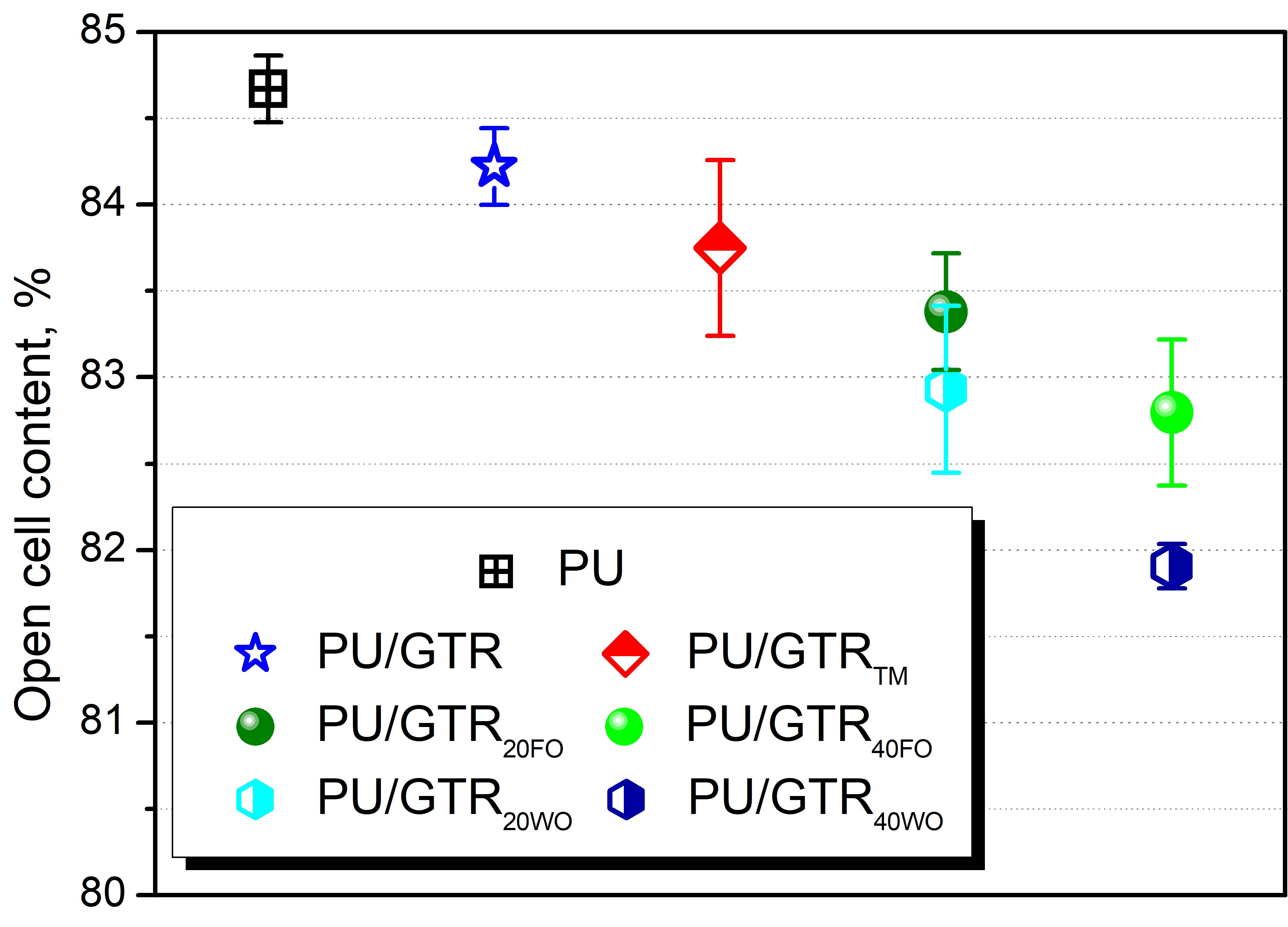

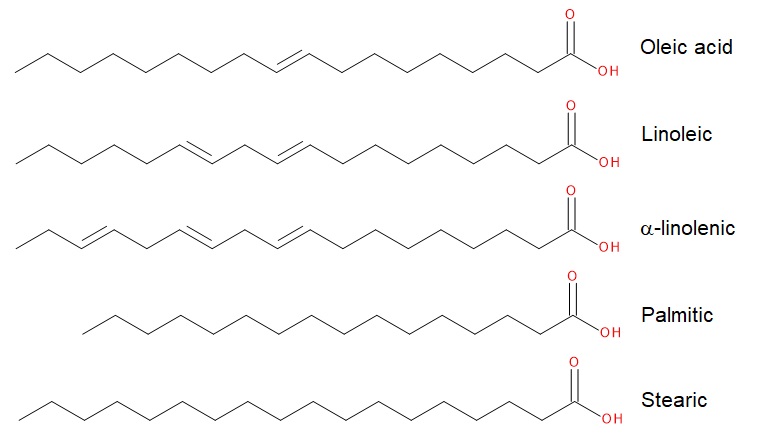

Ground Tire Rubber Filled Flexible Polyurethane Foam-Effect of Waste Rubber Treatment on Composite Performance

The application range of flexible polyurethane (PU) foams is comprehensive because of their versatility and flexibility in adjusting structure and performance. In addition to the investigations associated with further broadening of their potential properties, researchers are looking for new raw materials, beneficially originated from renewable resources or recycling. A great example of such a material is ground tire rubber (GTR)-the product of the material recycling of post-consumer car tires. To fully exploit the benefits of this material, it should be modified to enhance the interfacial interactions between PU and GTR. In the presented work, GTR particles were thermo-mechanically modified with the addition of fresh and waste rapeseed oil in the reactive extrusion process. The introduction of modified GTR particles into a flexible PU matrix caused a beneficial 17-28% decrease in average cell diameters. Such an effect caused an even 5% drop in thermal conductivity coefficient values, enhancing thermal insulation performance. The application of waste oil resulted in the superior mechanical performance of composites compared to the fresh one and thermo-mechanical modification without oils. The compressive and tensile performance of composites filled with waste oil-modified GTR was almost the same as for the unfilled foam. Moreover, the introduction of ground tire rubber particles enhanced the thermal stability of neat polyurethane foam.

Paulina Kosmela, Adam Olszewski, Łukasz Zedler , Paulina Burger, Krzysztof Formela, Aleksander Hejna

Journal of Composites Science

Structural Changes and Their Implications in Foamed Flexible Polyurethane Composites Filled with Rapeseed Oil-Treated Ground Tire Rubber

The utilization of post-consumer car tires is an essential issue from an ecological and economic point of view. One of the simplest and the least harmful methods is their material recycling resulting in ground tire rubber (GTR), which can be further applied as fillers for polymer-based composites. Nevertheless, insufficient interfacial interactions implicate the necessity of GTR modification before introduction into polymer matrices. In this study, we investigated the influence of rapeseed oil-assisted thermo-mechanical treatment of GTR using a reactive extrusion process on the processing, structure, and performance of flexible polyurethane/GTR composite foams. Applied modifications affected the processing of polyurethane systems. They caused a noticeable reduction in the average cell size of foams, which was attributed to the potential nucleating activity of solid particles and changes in surface tension caused by the presence of oil. Such an effect was especially pronounced for the waste rapeseed oil, which resulted in the highest content of closed cells. Structural changes caused by GTR modification implicated the enhancement of foams’ strength. Mechanical performance was significantly affected by the applied modifications due to the changes in glass transition temperature. Moreover, the incorporation of waste GTR particles into the polyurethane matrix noticeably improved its thermal stability.

Aleksander Hejna, Paulina Kosmela, Adam Olszewski, Łukasz Zedler, Krzysztof Formela

II International Scientific and Practical Conference SCIENTIFIC COMMUNITY: INTERDISCIPLINARY RESEARCH

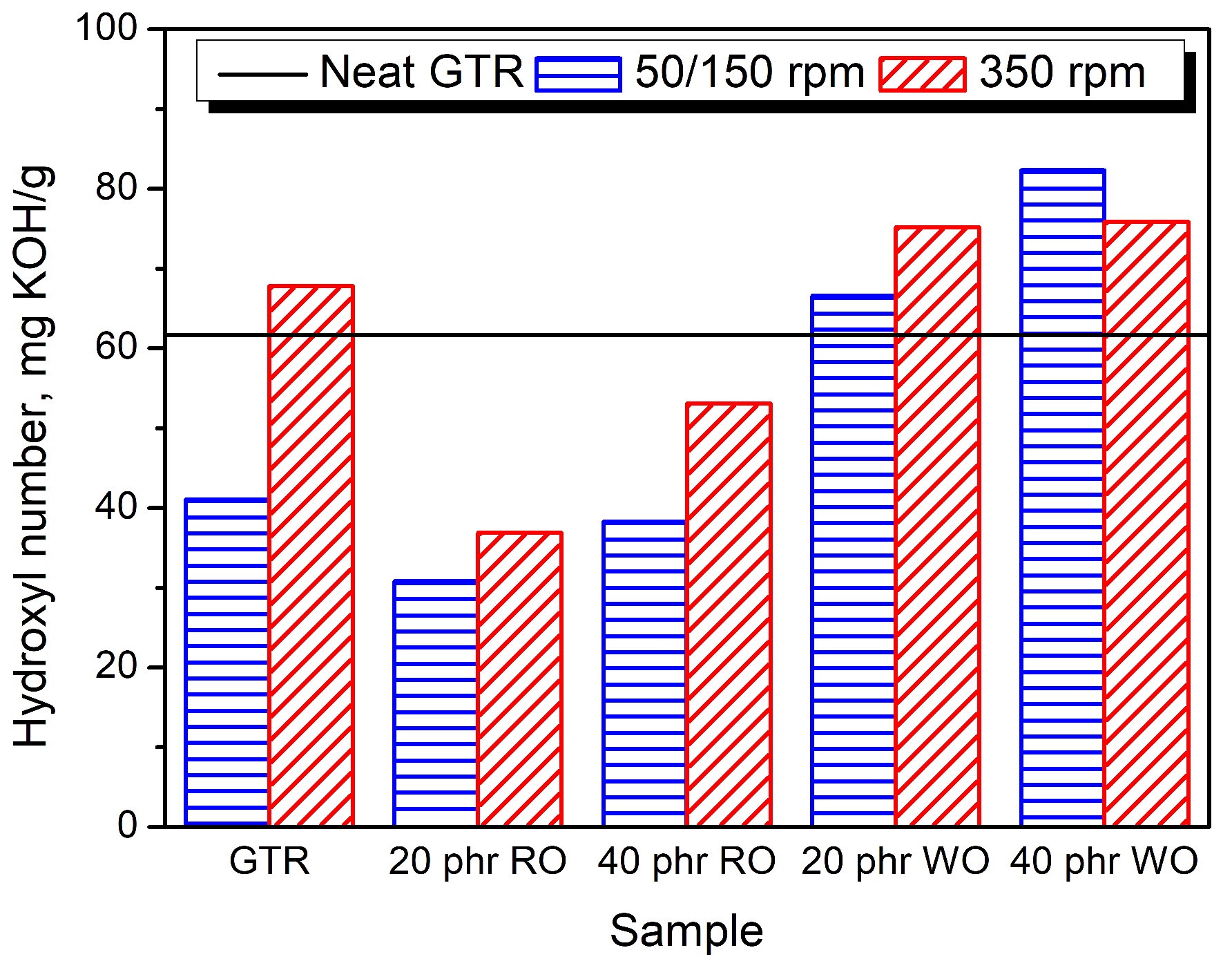

OIL-ASSISTED THERMO-MECHANICAL RECLAMATION OF GROUND TIRE RUBBER

Nowadays, it is crucial to seek for the methods of by-products and waste utilization, considering both environmental and economic factors. The example of waste material generated in the massive amounts, which requires the attention is ground tire rubber generated during recycling of post-consumer car tires. It can be applied as a filler into different polymer matrices, but to enhance its effectivity proper modifications should be performed. In the presented paper, we investigated the oil-assisted thermo-mechanical treatment of ground tire rubber in twin-screw extruder. Changes in the chemical structure were determined by the measurement of hydroxyl numbers of modified rubber. Moreover, application of oils enhanced thermal stability of treated ground tire rubber.

Aleksander Hejna, Adam Olszewski, Łukasz Zedler, Paulina Kosmela, Krzysztof Formela

Materials

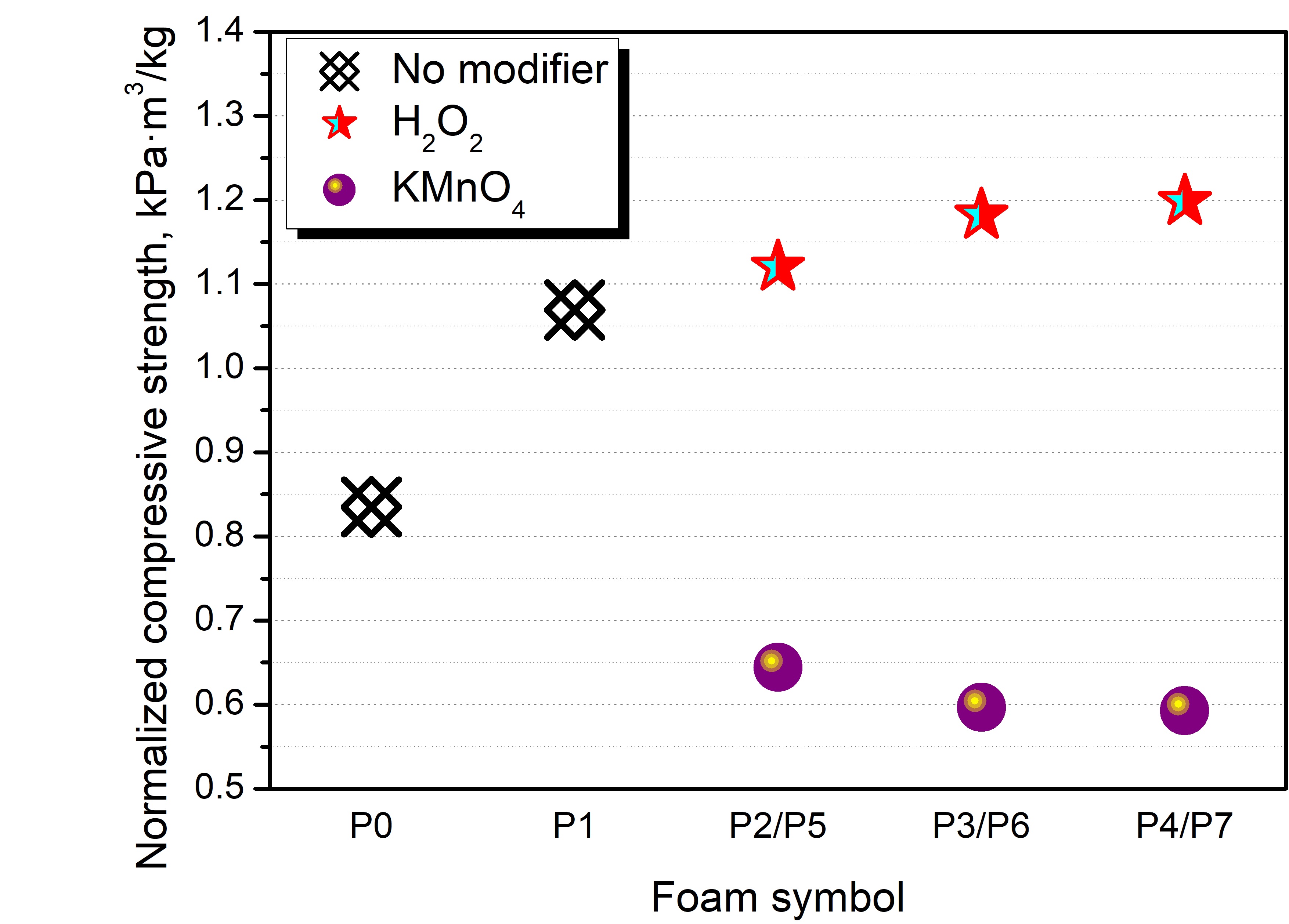

The Impact of Ground Tire Rubber Oxidation with H2O2 and KMnO4 on the Structure and Performance of Flexible Polyurethane/Ground Tire Rubber Composite Foams

The use of waste tires is a very critical issue, considering their environmental and economic implications. One of the simplest and the least harmful methods is conversion of tires into ground tire rubber (GTR), which can be introduced into different polymer matrices as a filler. However, these applications often require proper modifications to provide compatibility with the polymer matrix. In this study, we examined the impact of GTR oxidation with hydrogen peroxide and potassium permanganate on the processing and properties of flexible polyurethane/GTR composite foams. Applied treatments caused oxidation and introduction of hydroxyl groups onto the surface of rubber particles, expressed by the broad range of their hydroxyl numbers. It resulted in noticeable differences in the processing of the polyurethane system and affected the structure of flexible composite foams. Treatment with H2O2 resulted in a 31% rise of apparent density, while the catalytic activity of potassium ions enhanced foaming of system decreased density by 25% and increased the open cell content. Better mechanical performance was noted for H2O2 modifications (even by 100% higher normalized compressive strength), because of the voids in cell walls and incompletely developed structure during polymerization, accelerated by KMnO4 treatment. This paper shows that modification of ground tire rubber is a very promising approach, and when properly performed may be applied to engineer the structure and performance of polyurethane composite foams.

Aleksander Hejna, Paulina Kosmela, Adam Olszewski, Łukasz Zedler, Krzysztof Formela

VIII International Scientific and Practical Conference SCIENCE AND PRACTICE: IMPLEMENTATION TO MODERN SOCIETY

DETERMINATION OF THE HYDROXYL NUMBER OF GROUND TIRE RUBBER PARTICLES VIA MODIFIED TEST METHOD FOR ISOCYANATE GROUPS

Nowadays, considering the environmental trends and law regulations associated with the circular economy, it is very important to seek for the methods of by-products and waste utilization. The example of such material, which requires the attention and recycling method is ground tire rubber generated during recycling of post-consumer car tires. It can be introduced into various polymer matrices as a filler, but to enhance its effectivity it is essential to guarantee the interfacial compatibility. Therefore, the fast and simple methods for determination of the waste rubber chemical structure are needed. In the presented paper, we are presenting the method for the determination of hydroxyl number of ground tire rubber, based on the modified standard test method for isocyanate groups. Hydroxyl number is used as a quantitative measure of the hydroxyl groups content, which is essential during manufacturing of multiple polymeric materials, such as polyurethanes, epoxy resins, polyesters or polyamides. Moreover, the presence of hydroxyls on the rubber surface may be exploited during compatibilization of composites.

Aleksander Hejna, Paulina Kosmela, Adam Olszewski, Łukasz Zedler, Krzysztof Formela

1st International Scientific and Practical Conference SCIENCE, EDUCATION, INNOVATION: TOPICAL ISSUES AND MODERN ASPECTS

The impact of ground tire rubber treatment on the thermal conductivity of flexible polyurethane/ground tire rubber composites

Waste car tires are burdensome waste, and their utilization is crucial for the natural environment. In many countries, the primary method of their recycling is energy recovery, performed by simple combustion. However, material recycling is much more effective and significantly more beneficial for the natural environment. It results in the generation of ground tire rubber, which can be used to produce polymer-rubber composites. It should be considered as a method of waste rubber utilization. Moreover, it may significantly reduce the use of petroleum-based polymers. Therefore, the environment's total impact could be noticeably reduced, which should be considered a convenient step towards more “green” polymer composites. In the presented paper, the impact of ground tire rubber treatment on the structure and insulation properties of flexible polyurethane/ground tire rubber composite foams was evaluated.

Aleksander Hejna, Krzysztof Formela, Łukasz Zedler, Paulina Kosmela, Adam Olszewski

Proceedings

Recycling of Waste Rubber by the Manufacturing of Foamed Polyurethane-Based Composites-Current State and Perspectives

Worn car tires are disruptive waste, and the issue of their management is crucial for the natural environment. In many countries, the primary method of end-of-life tires utilization is energy recovery. However, more effective and beneficial for the environment is material recycling. Using them for the production of polymer-rubber composites seems to be an auspicious direction of research. Incorporation of ground tire rubber into polyurethane matrix should be considered as a method of waste rubber utilization. Moreover, it could significantly reduce the use of petroleum-based polyols and isocyanates, which are commonly considered as toxic chemicals. Therefore, the total impact on the environment could be noticeably reduced, which should be considered as very beneficial step towards more "green" polymer composites. This work aims to summarize the literature reports related to the foamed polyurethane/ground tire rubber composites. It particularly emphasizes the need for compatibilization of these materials by the enhancement of interfacial interactions between the polyurethane matrix and rubber filler phase, which significantly affect the performance properties of prepared materials. As an example, we presented our research results. Besides, future trends and limitations related to this type of composite materials are underlined.

Łukasz Zedler, Paulina Kosmela, Adam Olszewski, Paulina Burger, Krzyszfot Formela, Aleksander Hejna

Proceedings

Recycling of Waste Rubber by Thermo-Mechanical Treatment in a Twin-Screw Extruder

Recycling of waste tires is a significant issue considering both environmental and economic aspects. One of the leading recycling routes is the shredding of tires resulting in the generation of ground tire rubber. This material can be easily introduced into various polymer matrices as a filler, reducing the use of conventionally applied petroleum-based materials. In such cases, it is essential to ensure sufficient interfacial compatibility, which could be achieved by the proper modification of the rubber surface. Different methods of treatment of ground tire rubber aim to activate its surface and introduce functional groups, which could provide the possibility for interfacial interactions and incorporation of the significant amounts of recycled material. Therefore, in the presented paper, we examined the impact of thermo-mechanical treatment in twin-screw extruder on the appearance and chemical structure of ground tire rubber. Moreover, for each set of process parameters, the specific mechanical energy required for the processing was calculated, which could provide essential insights for the potential industrial application of the analyzed process. The energy demand should be considered as a very important issue during development of "greener" processes and materials.